WHO WE ARE

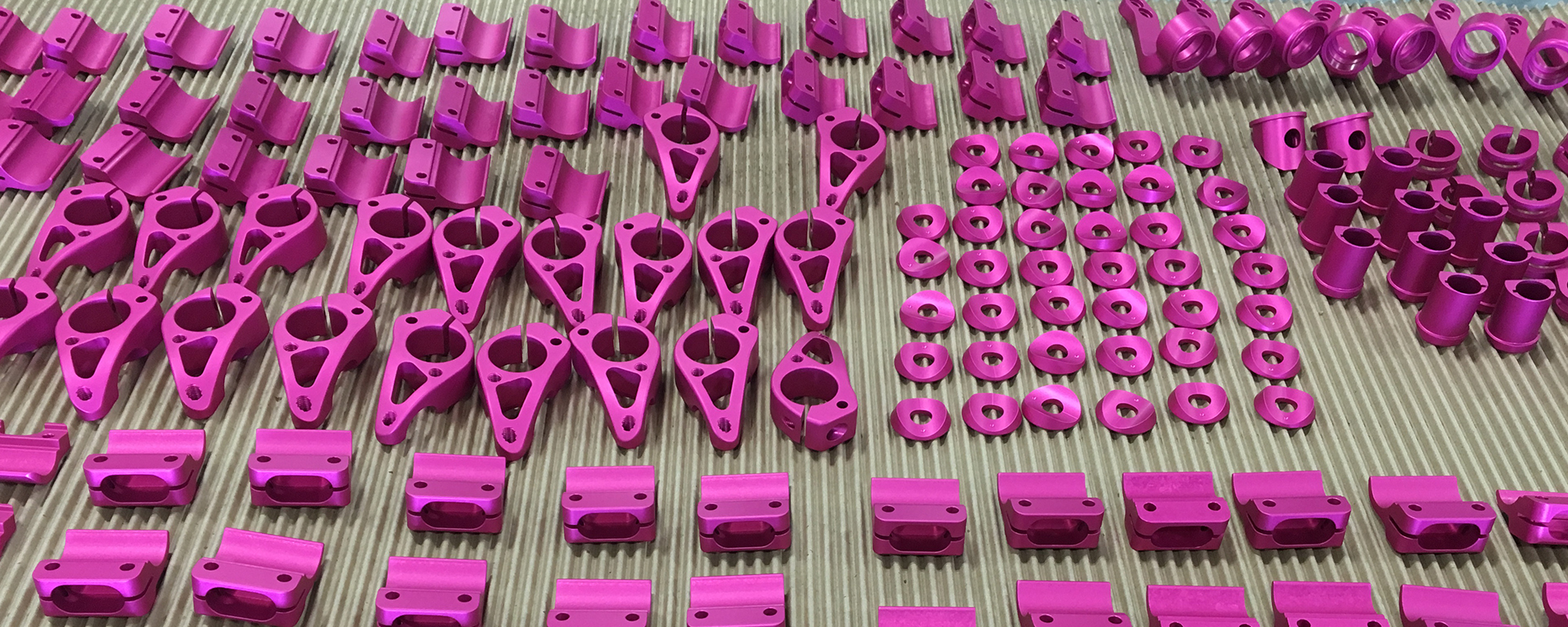

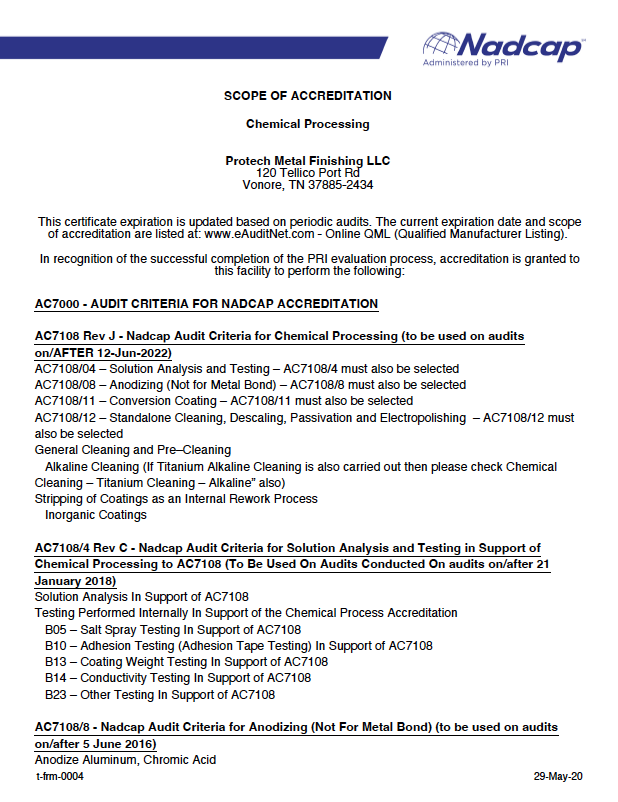

Protech is a woman-owned full-service metal finishing company that has served customers since 1980. Protech is housed in a 32,000 square foot facility on 10 acres in Vonore, Tennessee. Specializing in anodizing and rack plating. Protech services a large customer base in the Aerospace, Defense, Industrial, Medical and Automotive fields. We lead the industry in recruiting and retaining the most experienced plating and support personnel in the region.